Materials

Safety

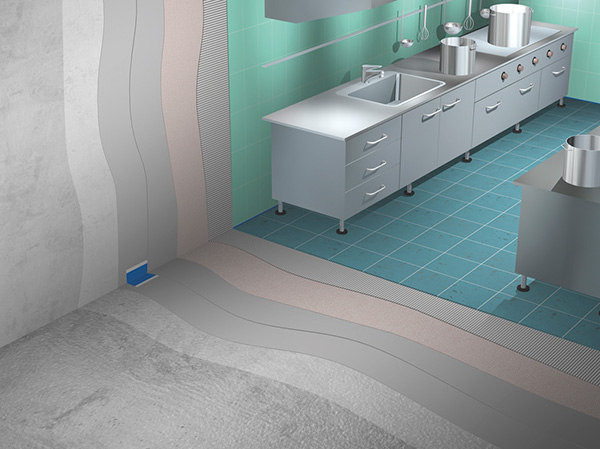

Master class for building kitchens: galley floors on cruise ships

Maritime environment demands a lot from various materials. Nowhere is this more apparent than aboard ships’ galleys where there is often a flurry of taxing activity.

Key Account Manager Herkko Miettinen from Saint-Gobain remarks that big ships upon high seas are a combination that requires special expertise with regards to durable kitchen floors.

“There needs to be a degree of flexibility in the galley floors, so that seams won’t crack, for example. At the same time, you need materials that are durable and light-weight.”

One of the hit product from Saint-Gobain in this area is Weber Marine VEM PU1, a two-component polyurethane levelling compound for producing viscoelastic sandwich structures.

“Modern ships place special requirements on the fire behavior and noise levels, and this product is really capable in both areas,” says Miettinen.

Galley floors that last

Provision Master Oy is one of the top makers of world-class marine floors. On Carnival Celebration, the company build a 309 square metre galley floor, and for the new Icon of the Seas vessel the total galley floor area was a whopping 1,759 sqm.

Managing Director Kimmo Häkkänen has 15 years of experience from making marine kitchen floors and he knows the challenge well:

“The sea requires the highest level of performance from kitchens. There are vibrations from the ship hull, trolleys with food or dishes travelling across the floors – it’s really a demanding setup. You need products that have been designed for marine use in order to make the cut,” Häkkänen says.

Keep learning!

Provision Master has been using Saint-Gobain products – such as Weber Epox Easy, Weber Marine Elastic 4660 and Weber Visco products – for years and also holds a Saint-Gobain Weber WVLU Certificate. This contractor certificate is a guarantee of high-quality work that meets the standards of demanding customers.

“We use Saint-Gobain Weber IMO-certified products that ensure a high-quality outcome for the customer each time,” confirms Häkkänen. “Weber Epox Easy, for instance, is a great product which remains flexible even after it hardens.”

Provision Master has also been pleased with Saint-Gobain Academy, located in Parainen, Finland, where training is given to contractors. “The training is on-going, which means that we are always up to date with new products and techniques,” Häkkänen says.

Expertise edge

Herkko Miettinen adds that shipyards are very mindful of certificates and standards these days – and glad to work with proven professionals.

“Turku shipyard, for example, uses only top level subcontractors in their ship projects,” he says.

More Information: tekniset.isover.fi

by: Sami J. Anteroinen